One-Stop FPC/RFC Assembly Services

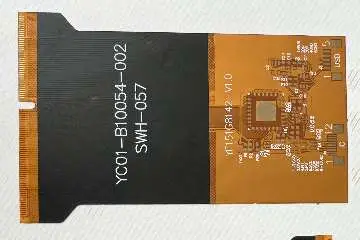

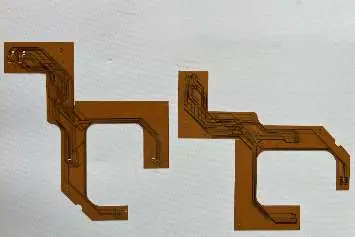

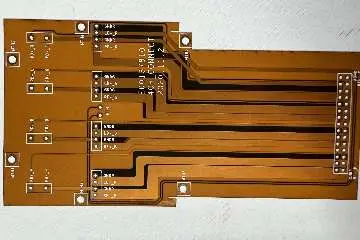

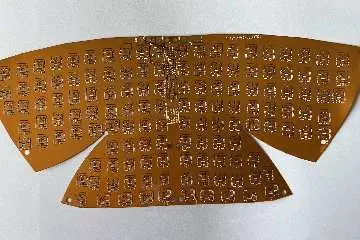

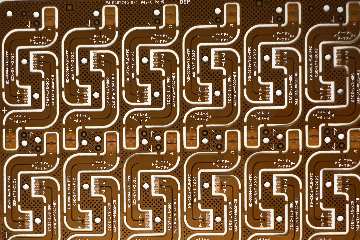

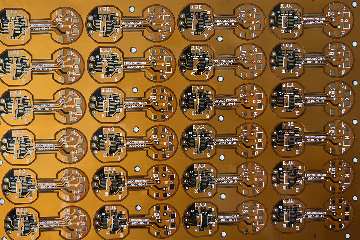

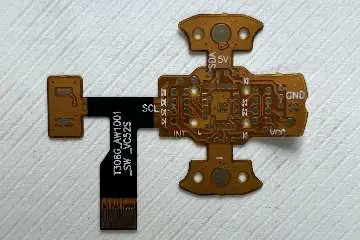

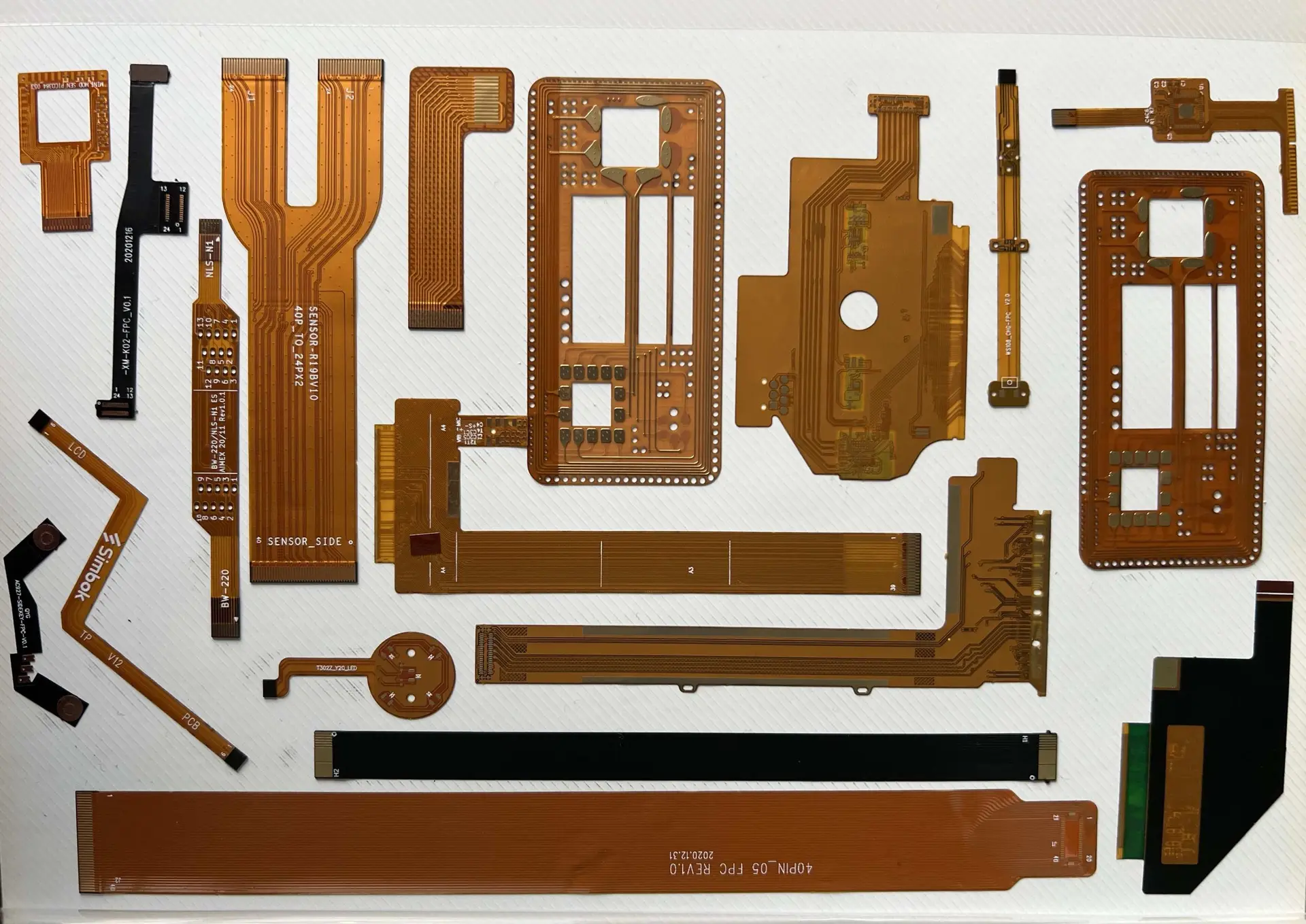

Full turn-key solutions for flexible printed circuits and rigid flex. PFC’s team has extensive design, development, manufacturing, and assembly experience providing high quality flex circuits. Our cutting- edge flex circuit technology enables freedom of design, product miniaturization, reliability, bendability, and overall cost savings for electronic solutions.

Our Services

FPC/RFC Manufacturing capabilities provide you with all you need to produce high quality all kinds of printed circuit boards t and FPC manufacturing offer you OEM service, including sourcing components, function testing, we’ll tell you how to optimize your order for your design priorities. After your first contact, we will assign one customer support to serve you, any questions, you can get the response immediately.

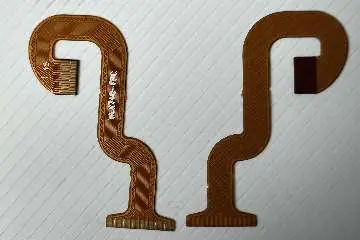

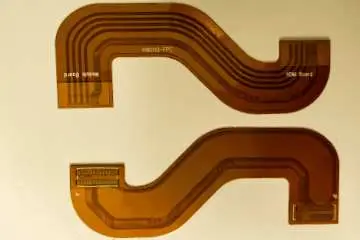

Single Sided

Double sided

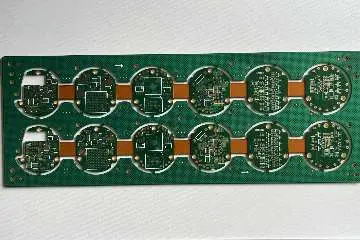

Multi-layer

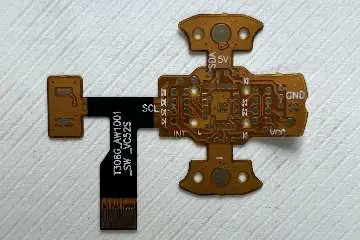

Rigid Flex

Sculptured flex

PFC High Speed Data Links

Our 6-P Process

Our 6-P Process ensures a seamless PCB manufacturing journey: Provide designs, receive fast Pricing, complete Payment, benefit from efficient Procurement, enjoy top-quality Production, and count on prompt Posting. This streamlined approach guarantees high-quality outcomes every step of the way.

Provide

Pricing

Payment

Procurement

Produce

Posting

Why Choose Us

No MOQ Requirements

You can order as few as one piece of FPC/RFC and PCA from us without any minimum order quantity (MOQ) requirements.

Fair Price

Our competitive pricing appeals to students and hobbyists for FPC prototyping and small-scale manufacturing.

Free DFM Check

Our engineers verify your FPC and BOM files for accuracy before starting production, ensuring a smooth process.

On time Shipping

Achieving a 98% on-time delivery rate showcases our dedication to customer satisfaction and operational efficiency.

Return and Refund

If our error makes a FPC or assembly unusable, we offer refunds, credits, or free rework and reshipment, requiring your cooperation for rework.

24 hours Customer Service

Our live customer service is available to assist you from file submission to receiving your FPC and assembled boards, ensuring your satisfaction.

Testimonial

Global Service Center

We have a global sales team available to assist you with FPC/RFC Manufacturing & Assembly services,Send your FPC files or Bom list now, You will get a quotation very soon !